“A couple times when I stepped on the gas, the engine made noise, but the car didn’t go anywhere for a couple seconds.” That was what Ariel told me yesterday after her evening commute. I had her drive Ringo around the block and park him in front of the garage. While backing down the driveway, I thought I sensed a stronger smell of gas than usual and filed that away to check once I had good light on the running engine.

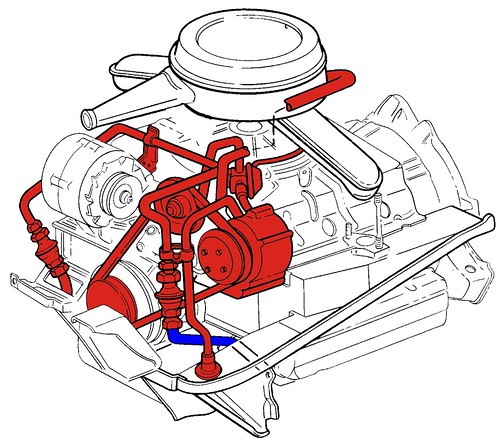

A quick look at the transmission dipstick with the shifter pointing at the D showed the fluid level about a quart low from full. After topping off with ATF, I checked the crankcase oil level which also needed a quart added. Since the low oil pressure woe seems like it’s behind us, I took the opportunity to remove the oil pressure gauge and the associated plumbing. In order to that, I first had to get the alternator out of the way to give me access to the threaded hole where the pressure switch mounts. With the negative battery lead disconnected, the nuts holding the wiring terminals off, and the bolts out, the alternator was free and the installation of the pressure switch into its hole was accomplished using the correct large socket (the one that prevents any leak-causing distortion to the switch body). The alternator went back on more easily than expected given the typically difficult to align forward, hidden bolt. Once the wiring was reconnected, the final touch was the positioning and tensioning of the fanbelt.

The engine started right up, and everything looked good, except for some dampness at the left carburetor inlet fitting. A snugging with a wrench and all went dry and I started to call it a night, but then Victoria, behind the wheel of Glinda, pulled down the driveway. She got out and informed me her car still had a rattling rearend. I pulled out a 7/16ths socket and applied a few more turns to the nut holding the slightly loose muffler strap. Again, only time will tell if I’ve conquered this nagging issue.