Thursday, December 12, 2013

I Can Rebuild A Carburetor

Monday, December 9, 2013

I Don't Mind Being Wrong

Given the weather conditions of this weekend past, I really should have dealt with him Saturday when temps were tolerable and the skies weren’t leaking white stuff, but my belief that his issue was beyond a simple fix caused me to put off the inevitable. As it was, Sunday was the day of reckoning. Planning for long-term times under the car, I felt it was mandatory to get him in the garage before commencing any repair. That meant, sadly, I needed to get TwoTone off the jackstands and out into the driveway. For that to happen, though, I had to repack the front wheel bearings, mount the two front hubs followed by wheels at all four corners, and put all the boxes of recently removed parts into the salon. Only then was I able to drop her to the floor. Oh yeah, at this point in the afternoon, there was now three inches or more of snow on the ground and on Ringo, so some quality time with a snow shovel and broom was required before I could roll any car anywhere.

With TwoTone out of the way, I climbed behind the wheel of the supposedly broken car and turned the key. Hmm. Started right up. Hmm. Settled into a smooth idle. This was nothing like I’d encountered a couple night earlier. I was able to drive him into the garage without a hint of a problem. As he calmly idled, I did the pull-a-spark-plug-lead-and-listen-for-a-drop-in-rpms test and all cylinders seemed to be contributing to the engine’s output. A quick-blip of the throttle revealed the problem as a slight banging commenced from the fuel pump area. I discovered the screw retaining the pump was loose. Less than a full turn with the ½ wrench followed by a snugging of the jam nut and all appeared good-to-go. With sleet now coming down and the lovely Loriann’s vehicle blocking my way to the street for a shakedown drive, I decided to quite while I was ahead. In hindsight I decided the loosening of the fuel pump caused a reduction in fuel flow until there wasn't enough left in the carburetor bowls to feed the engine as Ariel was cruising down the interstate to work.

This morning I was greatly relieved when he delivered me to work with nary an indication that only four days earlier I’d been convinced the sky was falling.

Friday, December 6, 2013

It’s Not a Blown Spark Plug

After a stop for dinner, we didn’t pull up in front of the house until nearly 8. I had high hopes of dealing with Glinda’s new carburetor (finish cleaning, rebuild, install, and adjust), but at that point it was too late to get involved in that project – plus I now needed to keep Glinda roadworthy for Ariel.

This evening I’ll prep the new carburetor and then back Glinda’s engine bay under the open garage door to hopefully keep out of the rain while swapping the new carb in for the passenger side’s racing carb. I’m sure it’ll be fun – NOT.

At some point this weekend the rain will stop and I’ll start diagnosing Ringo’s issue. Just like last time, a compression check of each cylinder will be my starting point, and where we go from there who knows.

Thursday, December 5, 2013

Here We Go Again

I love all my daughters, I truly do, but I do not like getting phone calls from the one driving a Corvair. It’s NEVER good news. Just a couple days ago I made the HUGE mistake of mentioning that Ringo was behaving himself. This morning he made me pay for that mistake by crapping out on Ariel during her drive to work. The ensuing phone conversation included the words, “chugging, backfire, sounds bad, gas smells.” This after she tried to clear out carburetors. I told her I’d be there with the tow vehicle when she gets off work this evening. Not sure what it could be, but I’m dreading the worst – another cylinder down the drain. It just occurred to me it could be a blown sparkplug. Hmm. That wouldn’t be too difficult to repair. Not really worth diagnosing a problem with only six words to go by though.

I guess it’s a good thing I picked up a rebuildable carburetor from Rich’s son, Vince, last night. After getting home I tore it down and it’s now soaking in carb cleaner. Once I determine the extent of Ringo’s issue(s), I’ll decide whether to fix him or work to try and get the new carb working on Glinda for Ariel to drive.

Never a dull moment.

Tuesday, December 3, 2013

We Have a Color Scheme

While Mikhaila is still pondering what her car’s final name will be, she has decided upon a color scheme:

- Exterior (except for roof): Fathom Green

- Roof: Ermine White

- Interior upholstery: White

- Carpet: Gray

- Interior Painted surfaces: Fathom Green (flattened to a semi-gloss)

By the way, Glinda is still leaving a puddle of ATF at each parking spot I place her in. This is quite disappointing, and maybe the magic elixir from Lucas takes a few days or so to effect a change. Regarding her gas mileage – it doesn’t look too promising.

Ringo has been out of the news lately – and that’s a VERY, VERY good thing. TYL!

Monday, December 2, 2013

Long Weekends are Wonderful

Two solid outings in the garage over the past four days and Mikhaila and I have got TwoTone nearly stripped down to the state where we can start bodywork. All that work and I can count on one hand the number of broken fasteners (one bumper bolt, one seat stud, one gas door screw, and one heater vent screw). At this point: the interior is empty except for the gauge set and the headliner; the trunk is empty except for the wiper motor, and the exterior is bare except for the door handles. Sadly, rusted-out areas were revealed as the trim came off – especially the rocker panel area at the front of the rear wheel opening. The floor has a couple holes about an inch-and-a-half in diameter. Both these areas will need to be cut out and new metal welded in. This, in addition to replacing the bashed-in left front corner, appears to be all the welding required.

Another sad discovery we made while clearing out the interior was that the brake lines had all been cut. I’m not sure why someone thought it a necessary act, but it will cost me some time and money to replace what looked to be solid, rust-free tubes.

Another sad discovery we made while clearing out the interior was that the brake lines had all been cut. I’m not sure why someone thought it a necessary act, but it will cost me some time and money to replace what looked to be solid, rust-free tubes.On the Glinda front, I re-reassembled the “bad” carburetor from TwoTone and installed it in place of the left carburetor (let’s call this one an original). The engine would not run right, so I’m writing that carburetor off completely and will obtain a rebuildable replacement from Vince (Rich’s unsold stash). The original went back on and a test drive around the neighborhood proved to me she’d probably get me to and from work. So, today I pressed her back into daily-driving duty. My first stop of the morning was the gas station where I put in about $40 of 93 octane. I texted Fuelly.com the mileage and amount it took to fill the tank and immediately received a text back telling me that the last tank-full elicited a whopping 11 miles per gallon. My hope is putting the new carbs on will return the mileage back to the 18-19 range I was seeing before I put on the carbs with the relocated jets. To add insult to injury the leak from the rear of the transmission is getting worse. I happened to have some Lucas transmission treatment on the shelf, so I poured a pint down the fill tube and we’ll see what happens.

Monday, November 25, 2013

Time and Money Spent on TwoTone

The Glinda work consisted of using her engine to determine which subassembly of TwoTone’s rebuilt carburetors is bad. As I posted last week, one carburetor assembly appeared to function properly, while the other wouldn’t work right when bolted to the Glinda’s left head. So, on Friday I created a table like the following (yeah, I am an engineer):

| Wouldn’t Work | Seemed to Work | |

| Bad Top | Good Top | |

| Bad Cluster | Good Cluster | |

| Bad Bottom | Good Bottom |

With the assumption that only one portion of the bad carb was causing the malfunctioning, I swapped both the Bad Top and Bad Cluster onto the mounted Good Bottom. While the engine started and ran fairly smoothly, the right side would not heat up telling me it wasn’t getting the proper flow of fuel. Off came the Bad Top and back on went the Good Top. This time the engine ran nicely and soon after the restart, the choke opened up all the way. With the engine fully warmed up and shut off, I hooked up my length of clear tubing with some water in it to the vacuum ports on the two carbs. With the engine running again and the left carb disconnected from the throttle shaft, I turned that carb’s idle screw in until the water was static in the tube. I then turned the small linkage rod until its end lined up with the hole in the throttle shaft. The new carb was now balanced with Glinda’s old carb. Before quitting for the night, I disassembled the presumed bad top and dropped it into the carb cleaner for a good soak. Referring back to my table, the two carbs now looked like this:

| Installed & Working | Unproven & Soaking | |

| Good Top | Bad Top | |

| Bad Cluster | Good Cluster | |

| Good Bottom | Bad Bottom |

Saturday afternoon, both Mikhaila and I had finished our house chores and we headed to the warmed-up garage (I’d gone out about an hour earlier and fired up two of the kerosene heaters). She started by spraying gloss black Rustoleum on the front brake backing plates while I emptied out a bin to collect TwoTone’s removed parts. We then worked together to empty out the salon (interior space) of all the loose pieces I’d stored there. We found some new parts that will be used in the roadification. Next, we moved on to removing the seats. All the fasteners but one were cooperative. I slathered the stubborn nut with the magic elixir of 50/50 acetone/transmission fluid. We’ll let that one sit a while. The final actions for the day were removing sill plates, vent grills and covers, and the seatbelts. Once that last nut is loose, we’ll finish exposing all the floor and Mikhaila can have fun with the wire brush getting rid of any loose rust.

Speaking of rust, I can’t say it too many times - disassembling this car has been quite a treat compared to previous projects. As mentioned before, only one threaded joint out of a couple dozen was seized. We’re quite fortunate to have landed another barn find (Heidi was the other one and more accurately they were garage finds).

Finally, this morning I got on the phone with Clark’s and placed an order for POR-15 for coating TwoTone's floor, a bunch of carpet, paint, and upholstery samples (more on that later) and three wheel cylinders (there was a brand new right front cylinder assembly amongst the parts we pulled out of the salon). Not wanting to pay the nearly $100 for a rebuilt master cylinder, I hopped on Amazon and bought an aftermarket dual master cylinder for $33. I’ve decided I’ll do the conversion to dual from single (1964s only came with a single master cylinder). I’ll need to buy some fittings and a couple short brake lines, but I’ll do that once I have the master in hand. The running expense tally on the sidebar has taken a hit. Won’t be long before we’ve topped a grand.

I mentioned samples – it looks like Mikhaila has a color scheme for this car. She shared with me that she likes a darker green for the body with a white top. For the interior she’s thinking white seats and door panels, black carpet, and a flatter version of the exterior green for the exposed interior metal (dash, doors outside the panels, etc.). I pulled up a photo of a 1960 Corvair in Jade Green, and she liked it so one of the samples I ordered was for that color. The other was for a Fathom Green from 1969. Much darker, but not nearly as 50s as she mentioned she was going for.

Friday, November 22, 2013

What A Way to Start the Weekend

This morning, after dropping Mikhaila at her bus-stop, I made the hour drive up to 1079 Bon-Ox Rd – the Corvair Ranch. A couple months back, I called Jeff there and asked him if I could come and harvest shifter and clutch parts off a LM. He was kind enough to tip a convertible on its side for me, and this morning was my first chance to get up there. It was a good thing I chose today since it’s predicted that this is the last day with sixty degree temps until next Spring.

This morning, after dropping Mikhaila at her bus-stop, I made the hour drive up to 1079 Bon-Ox Rd – the Corvair Ranch. A couple months back, I called Jeff there and asked him if I could come and harvest shifter and clutch parts off a LM. He was kind enough to tip a convertible on its side for me, and this morning was my first chance to get up there. It was a good thing I chose today since it’s predicted that this is the last day with sixty degree temps until next Spring.I arrived around 8:30 and got right to it. Off came the rear tunnel cover followed by the heater duct (the forward tunnel cover was already off). The mount nuts holding the rear crossmember in place were challenging to remove, but with the aid of my largest prybar, they succumbed. The rest of the removal went well, and Jeff supplemented the parts I pulled with the missing clutch rod and fork. I think there are a couple other shifter parts I’m missing, but now I’ve got an excuse to go back there.

I always enjoy my visits to the Ranch – the great conversation (keeping Jeff from his job) and the seeing so much Corvair. Jeff tried to sell me a ’64 Monza coupe (running 110HP with a 4-speed transmission) telling me it would be a good solid start to a project even though it needs all the brakes redone and new floors. I checked it out, and he’s right – it is nice and solid other than the floors. It will also need its front valance replaced and a patch welded into the dogleg portion of the left front fender and a new interior and a paint job, but hey, that’s what a project is. He’s willing to let it go for $800. I should’ve taken some photos of it, but since I’m not adding to the fleet, it didn’t happen.

Click here to see the set on Flickr of the photos I took this morning.

Wednesday, November 20, 2013

Let the Swap-a-Carb Game Begin

I did, however, don some grungies last night and went out to the driveway to play swap-a-carb with Glinda. I pulled off the current left side carburetor and bolted on the recently re-rebuilt carb of TwoTone. Sadly, the engine would not run right and the entire left bank of the motor stayed cold, so that carb is still non-functioning. After yanking that one off and replacing it with the TwoTone’s other carb, the engine went back to normal – at least normal when defined as “the engine idles smoothly, revs easily, and doesn’t send copious amounts of dark exhaust into the night sky.” I need to put some miles on the car before I determine if the left carb caused the gas guzzling. Before I do that, I’ve got to balance the new carb to the existing left side one. That’ll wait for another evening.

An additional exercise will be to swap the internals and lid from the still non-functioning carb over to the working one on Glinda’s engine’s left side. Not as critical to Glinda’s problem, but I do need to figure out what’s causing TwoTone’s other carb to malfunction – my bet is there’s still a clog in a passage of the carb’s base.

Now onto the paragraph Corvair purists may choose to skip – the paragraph where I regale you, gentle reader(s), with the story of my conquering the truck’s rear end (gee, that sounds dirty). Anyway, last Friday I was lying under the truck on the cold concrete of the driveway and all went amazingly well. The forward bearing was liberally lubricated with gear oil and place into its race. The seal was greased and installed with the gentle persuasion of a hammer via a 4X4. The balance of the pinion assembly was slid home from the back of the pumpkin. The yoke’s spline was greased before being engaged with the pinion’s front end. The washer and old nut were used to apply just enough torque to crush the crush sleeve with only about ten foot-lbs of effort to turn the pinion. The old washer and nut were replaced by the new washer and locknut with liberal amounts of Loctite on the thread to give added insurance against the same problem reappearing. The differential assembly with ring gear and bearings were rolled into place. The spacers filled the gaps on either side. The axles were shoved into engagement and c-rings installed followed by the diff pin and locking screw. The cover was bolted into place with a new gasket. About two and a half quarts of gear oil were squirted in until the level came up to the bottom of the fill hole. The plug was reinserted and it was test-time. I turned on the engine, put the shifter in D, and walked to the rear to listen for any untoward noises. All was quiet, so I bolted on the wheels and dropped her off the jackstands. The next morning’s drive to and from the dump was uneventful – in fact she has no vibrations from the rear at all (surprise, surprise). A big TYL that that project’s behind me.

Thursday, November 14, 2013

Must Make Her Rollable

Last night, at the dinner table, I blurted out that Mikhaila and I had to spend some quality time with her car. I went on to explain that, with all the bad luck I’ve been having with the fleet and the onset of brrr-cold nights, I needed to be able to roll TwoTone out of the garage to make room for the next daily-driver that craps out. In order for that happen, I went on, she and I needed to finish the work we’d started on the front end. Loriann asked how long that would take, and I replied three hours of Mikhaila’s wire-brushing, priming and painting the brake backing plates would be her commitment, while I would then rebuild the brakes, pack and install the wheel bearings, and bolt on the hubs and wheels before lowering her off the jackstands.

Mikhaila offered to go out to the garage that night and get started, so right after dinner, I fired up a couple of the kerosene heaters. Thirty minutes later she and I were hard at work – her wire brushing the right front backing plate while I disassembled the brakes on the left. By the end of the evening, all the priming was done. A couple coats of gloss black Rustoleum and some cleanup on the seal surfaces is all that’s left to do before I bolt up the mix of GNP and GUP brake components.

Yesterday I blogged about unreliable my memory is. Well, it’s not quite all gone. As I gathered up the recently cleaned front wheel bearing parts, I inspected the front seals and pronounced them unusable. I actually remembered seeing new Clark’s replacements in a box, so I went to the shelves, opened the box I thought they were in, and pulled out the package with C319A written on the outside. There were, in fact, EM wheel bearing seals. Inventorying all the GNPs I’ve got in assorted boxes is still on my general to-do list.

Since the garage was warm and my clothes were grungy, I moved on to other projects. I took apart TwoTone’s left side carburetor and dropped the body into carb cleaner. This was the carb that seemed dead when it was bolted onto Glinda’s guzzling engine a few days back. It’s my hope to prove out both carbs before they’re used to fire up TwoTone’s long-dormant engine. At the same time, installing them onto Glinda’s engine should prove or rule out her current carbs as the cause of abysmal gas mileage she’s currently getting.

Finally, I unpacked the Amazon.com box that had showed up earlier in the day. Out came the carpeted speaker boxes which were immediately filled with my new 6X9 speakers. Not sure why I’m spending time and money on a car that I’m really disgusted with right now, but I started down this path of going beyond AM before Glinda began misbehavin’.

Wednesday, November 13, 2013

Doing Some Digging

When I started blogging waaayyy back in April of ought-two, I had a number of reasons to record the highs and lows of the Corvair portion of my life. One of them was I knew I wouldn’t be able to trust my memory to dredge up every swap and adjustment I’d made over the years. “When, if ever, did I replace Heidi’s generator; or did I just rebuild the one that came with her?” “Is Ringo still running the same set of sparkplugs that went in when I rebuilt his engine, and when was that?” “Have I ever done anything with Glinda’s distributor?” The only way I would find the answers to questions like those – questions I really wanted answered – was to write (or in this case type) it all down as it happened.

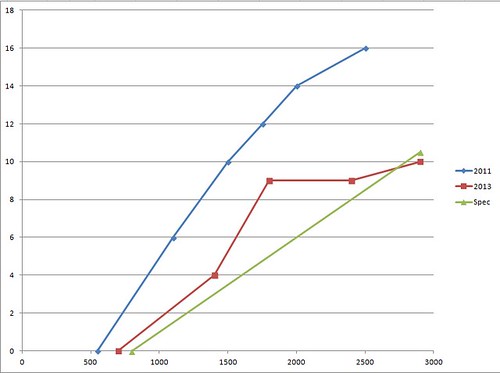

This morning I was messing around with my all-inclusive Corvair spreadsheet and discovered I’d created another graph at some point showing Glinda’s advance versus rpm curve. That prompted me to search this blog using the keywords Glinda and distributor to see what I may have posted using the graph. Over a dozen posts popped up including the one dated February 3, 2011 where I discussed that old graph. At that time she was Victoria’s daily-driver and I was – surprise, surprise – trying to improve her gas mileage. I wrote that I’d gotten a list of things to check in reply to a CorvairCenter posting one of which was to verify that the proper distributor was being used since Chevy supplied different distributors with different advance curves depending on the engine/transmission combination. Not being able to find the number, I, instead, measured and plotted advance versus rpm. Take a look above where I've put up a new graph showing advance then and now compared to a revised spec curve. The interesting thing was the curve I plotted nearly two years ago does not match the curve I generated yesterday. Even more compelling is the old curve shows more advance than Chevy intended. With these anomalies, I went searching through the other posts to determine when, if ever, I’d replaced Glinda’s distributor.

Here’s a distributor time-line for Glinda. 12/9/2010: replaced original distributor with one from the shelf. 1/17/2011: rebuilt original distributor. 1/20/2011: finished rebuilding the original distributor. 1/25/2011: installed rebuilt original distributor. 2/8/2011: noticed dwell movement. 2/11/2011: made graph. 5/17/2012: rediscovered changing dwell. 6/21/2012: replaced points plate. 11/6/2012: noticed fuel improvement, attributed to "rebuilt distributor".

So where do I go from here? Well, first I’ll open up the distributor, remove the points plate, and thoroughly clean and lubricate the weights and springs with the hope that more advance will kick in. More is better unless it results in pinging. Second, I still believe the carbs are running rich, so I’ll try to get TwoTone’s rebuilt carbs corrected and swap them on to Glinda to test my theory. Finally, as a buddy of mine at work is urging me to do, I’ll “just get the 140/4-speed project done and installed.”

Feel free to bypass this paragraph regarding the ongoing truck saga if you are only here to catch up on Corvair activities. As I reported yesterday, the seal I’d gotten hadn’t fit correctly. I decided to bite the bullet, pay the big bucks, and go to the Chevrolet dealership to get the “right” parts. After calling the parts department and giving them the truck’s VIN, the parts counter-person looked up the yoke kit (which includes a seal) and lo-and-behold they came up with a part number different than the one I’d bought online. They had the kit in stock, so my VISA card took a $160 dollar hit, but I was still happy to walk out of there with “right” parts. I got home and immediately walked to the truck to compare the “right” parts with those I’d pulled off the truck. To my IMMENSE disappointment, the “right” parts I’d bought were not right. The yoke was much significantly larger and there was no way it would work. A phone call this morning to the dealership, with a different counter-person on the line, and I now have a different part number for the “right” kit. Of course, he had no idea why my VIN spat out the wrong part number yesterday. Today I was smart enough to bring the old parts in with me so when I went there at lunch, I was able to set new and old side-by-side and it appears they are the same this time. The part’s guy did a little research and discovered the VIN he’d heard me tell him over the phone yesterday had an E, rather than the Z it should have – he misheard me. To add insult to injury, the right yoke is smaller than the wrong yoke, yet it cost me an additional $19.

Tuesday, November 12, 2013

My Head Hurts

With that roadblock firmly in my way, I chose another path and grabbed work light, dwell meter, timing light, notepad, and pen and headed out to the curb where Glinda sat. In response to yesterday’s blog post, I received a comment that I should check the centrifugal advance of Glinda’s distributor since a lack of advance at higher rpms would be detrimental to her fuel mileage. I hooked up the timing light, disconnected and plugged the vacuum advance hose, and fired up the engine. With the light aimed at the timing marks, I revved the engine and watched with a little sadness as the timing climbed with the rpms. Okay, it’s moving, but is it moving enough? I hooked up the dwell meter and flipped its switch to tachometer mode. After begging Mikhaila to come out and “drive” the car for me, I had her press and hold the gas pedal at different engine speeds while I measured the timing. The following graph shows the different advances I measured plotted against the spec’s straight line values.

The differences are probably just due to not being able to hold the rpms perfectly steady. Regardless, the centrifugal advance weights seem to be doing their job inside the distributor.

On to vacuum advance. The spec says I should be seeing 24 degrees of advance when the carburetor port is sucking air at a level of fifteen inches of mercury. I hooked up my vacuum gauge and determined Glinda’s engine hits this mark at around 2000 rpm. With the vacuum advance tube reconnected to the advance on the distributor, I turned the engine back on and noted the advance due to vacuum was about 8 degrees. When I revved the engine up to the aforementioned 2000 rpm, it jumped up to 17. Bear in mind, gentle reader, that part of this jump was due to centrifugal advance. If I back out the centrifugal advance at 2000 rpm, I end up with only 10 degrees instead of the required 24.

Thinking this was an aha moment, I awoke this morning with hopefully simple task of swapping out Glinda’s current vacuum advance with one from a distributor on the shelf. I did that, but it doesn’t look like it’s made much difference. Only time (and miles) will tell. One other thing I’ll check (thanks to a Facebook post from a ‘vair guy) are a plug from each bank. If one is sooty, then that carb is running rich and I’ll swap it out for the one good rebuilt carb from TwoTone.

Monday, November 11, 2013

Glinda’s A Guzzler

That night, I needed to first deal with the leaky exhaust before going further with her thirty ways. The crux of the exhaust problem was a bad gasket (donut, packing) between the left exhaust manifold and the exhaust pipe. As is nearly always the case, the fasteners at this joint were a rusty mess barely resembling a nut and stud. Knowing there was no way I’d be able to cleanly undo that joint, I was prepared with replacement GUP manifolds complete with stainless studs and brass nuts as well as a set of GNP gaskets. As expected it didn’t take much effort to wring off the nuts and the associated portion of each manifold stud. With the pipe disconnected, the six nuts holding the manifolds were far more cooperative and the old manifolds were free in no time at all. With new gaskets the replacement manifolds were bolted into place followed by reattachment of the exhaust pipe with its new gaskets. With the car still up on ramps to listen for leaks, I turned the engine on and my efforts were rewarded with a much quieter condition and no leaks detected. A silent CO monitor will be the final proof, so I'll only know after I put some miles on the car with the heater on full-blast.

Back to the mileage issue. I decided to try swapping out the current carburetors for the set Mikhaila and I recently rebuilt for TwoTone. Once everything was hooked up it took a few cranks to get some gas into the bowls, but the engine eventually fired up. Sadly, one of the carbs was not working. Something must be clogging the jet or an inner passage. With that disappointing discovery, I got to remove those carbs and bolt back on the old carbs.

The next morning I drove down the interstate and was able to seemingly watch the needle descend - an indicated quarter tank burned in about 40 miles of driving. That’s about 13 mpg. Arghhh! The next fix I tried was replacing the fuel pump while not hooking up the vapor return line. If the leak is in that line, I wanted it out of the equation. Sadly, more driving yesterday showed apparently no improvement.

While I was still in grungies, I spent some time later that day clearing out more parts I’ll never use. They went into the bed of the truck freeing up some shelf space in the garage. With that done, I turned my attention to TwoTone. I first cleaned all the bearings and stuff we’d removed from the front hubs. Then I finished disassembling the right front brake system. It’s now ready for Mikhaila to wire brush clean and then coat with Rustoleum rusty metal primer and black paint. Then we’ll be able to put the brakes and hubs back together and drop the car back to the floor.

Oh yeah, I almost forgot. I worked on Luna too. Whilst putting Ringo back on the road I needed to borrow a couple items off Victoria's car - the alternator and the choke tripper. Clark's came through with a new tripper and I tore down Ringo's loose alternator, inspected everything, and put it back together without any of the slop there was there before. Not sure what I did, but I hope I did it right. With those parts put back on the engine, it’s back where it was a year ago. Victoria and I have had some conversations about Luna. She is soooo busy I can’t imagine her ever having time to take a weekend off to help me install the convertible top on her car. She promises she’ll turn down some nanny jobs and will be able to get the top on early next spring. With that in mind, I told her I would squeeze some Luna-time into my schedule. That car, while able to stop and go, has a number of issues that should get corrected before it can be considered reliable transportation. It too, seems to have a gas issue. The few times we’ve tried to take it out, we’ve ended up having to put about three gallons of gas into the tank in order to get it to start. Since the gauge doesn’t work, all we know is that it won’t start, we pour in three gallons, and it starts. Anyway, that needs to be resolved (I’ve got a couple gauges of suspect condition I’ll swap in before pointing my finger at the fuel sender in the tank - although I even have a GNP for that).

Monday, November 4, 2013

And On We Go

A brief paragraph on the fleet’s main support vehicle, the truck, and the nasty noise emanating from its rear end (typing that brings a childish smile to my face). I never made it to the dealership. Instead, I put the backend up on jackstands, pulled off the rear wheels, and had Mikhaila “drive” (operate the gas pedal) while I looked and listened for the source of the VERY nasty sound. It didn’t take long to discover the rear portion of the driveshaft start to bounce around as the truck’s indicated speed slowly climbed. After Mikhaila stepped on the brake and put the shifter in Park, I slid farther underneath and jiggled the u-joint. The sloppiness in the yoke indicated that, at best, I needed to replace the differential’s pinion bearings. The dealer only wants $1300 to do the job. Seriously????!!!! The price for new bearings, seals, and gasket was, online, less than $100. Since then, I’ve read a couple online descriptions of the work, and while tricky, it certainly wouldn’t warrant my forking out the price of one-and-a-half Corvairs. So, once I verified the ring and pinion are still in good shape, I’ll be visiting RockAuto.com and ordering their Differential Overhaul Kit.

Finally, on to Glinda and her frustrating fuel delivery issues. Last Wednesday it only took me about thirty minutes to R&R the fuel pump with a GUP. A subsequent short test drive that included a full-throttle blast up the highway proved the fuel pump was not the issue. To me that’s a good news bad news thing. Good that I’ve still got a spare fuel pump. Bad that I need to dig deeper to get Glinda reliably roadable again.

On the way home from work the next day, I stopped by CarQuest and bought another inline fuel filter. Once I put Glinda’s right rear up on a jackstand and removed the wheel, I liberated the old filter and immediately thought to myself why didn’t the manufacturer make the filtering medium a different color than rust. Just moving the still fuel-filled filter created a cloud of rusty particles giving the part a snow-globe appearance as I peered through the transparent plastic housing. The new filter went in smoothly, but before the test drive, I took advantage of the raised rear and installed the two lower shrouds so Mikhaila and I could have heat during our morning commute (her to the bus stop, me on to my work). With all wheels back on pavement, the moment of truth was here. The sixty-five mile per hour blast that had brought the car to its knees only yesterday had no negative effect on her this time. TYL – another issue eradicated. An additional item was also crossed off the to-do list. For quite a while, stomping the gas pedal resulted in the engine dying. I’d been attributing this adverse behavior to bad carburetors, but the problem all along had been low fuel levels in the carb bowls.

Friday morning, fifteen minutes after I cranked up the heat during the morning commute, the carbon monoxide detector began to let me know that fixing the exhaust leak needed to be moved to the top of the to-do list. So that’s what I’ll be doing this evening. It’s always something.

Tuesday, October 29, 2013

Can It Get Any Worse?

Well, of course it can, but right now things seem pretty dismal. While Ringo is back on the road and appears to be behaving, I still have two misbehaving vehicles – Glinda and the truck. The fuel issue with Glinda has been a real pain. After last night, I feel I’ve narrowed it down to the fuel pump. Yeah, yeah, I should’ve started there, but the frugal engineer I am was intent upon to misinterpret the symptoms and fix everything else but the real root of the problem. The truck has recently developed a horrible noise that I need the dealership to diagnose. Anyway, back to the specifics of the fleet work.

This weekend I spent part of Saturday afternoon in the garage stripping the bottom seat upholstery I’m trying to reuse off Ringo’s old driver’s seat. To do that I first needed to separate the bottom from the back which, fortunately, wasn’t too difficult. I then brought up my sewing machine from the basement and replaced a piece of rotten cloth on the seat cover. After putting some Gorilla glue over a cracking seam, I set the cover aside while I stripped the upholstery off the replacement seat bottom. Sunday afternoon I was back in the garage hog-ring pliers in hand putting black seat cover on new (to me) seat bottom frame. After bolting the seat into Ringo, I called Ariel and told her to come get her car.

Yesterday I pulled Glinda’s right front wheel up a ramp so as much gas as possible would shift away from the bottom access hole. After disconnecting the hose, I drained about three gallons out before the stream stopped allowing me to remove the fuel pickup assembly, and replace the sock that filters the gas going into the fuel line. The only problem was the sock I was sure I had was nowhere to be found. Irr. Knowing I had an inline filter farther down the line, I reinstalled the assembly without a sock. This morning I confidently sat behind the wheel and entered the beltway getting up to speed with no problem. Sadly, that confidence was dashed against the rocks a mile later when the motor quickly ran out of oomph and I barely made it to the next offramp. I nursed it home only having the engine die three times before I was able to back her down the driveway. I swapped key rings and drove the truck to work (with all its untoward noises). Tonight I replace the fuel pump.

Thursday, October 24, 2013

Ringo’s Almost Ready for Ariel

While I didn’t drive him Tuesday (and I’ve reported what a mistake that was), I have been using him during my daily commutes and he’s performed flawlessly (TYL). The finaly item on the to-do list installing the replacement driver’s seat. I’m putting off starting this until tomorrow night so I can do the swap in one fell swoop to minimize his time off the road just pull the current one out, skin it of its upholstery, skin the replacement, and put the vinly on the replacement before reinstalling with swapped hardware.

Wednesday, October 23, 2013

Starvation is Bad

Monday, October 21, 2013

New Parts are Oh So Nice

The above photo tells it all. Ringo is NOT up on jackstands in our driveway anymore, nor is his engine dripping 30 weight all over the pavement. Yesterday, I successfully completed replacing his #2 piston and cylinder.

The reassembly actually started Friday night when I carefully installed the oil and compression rings before cautiously tapping the assembly, bound by my ring compressor, into the well-oiled cylinder. I then took that over to the engine, guided the open rod end with its lubricated bearing half onto the crankshaft while inserting the cylinder into the bore of the engine block. Next, the cap with the other bearing half slathered with grease went on followed by the two nuts which were torqued down per the manual’s specification. With rain predicted, I wanted to get the crankcase cover reinstalled to protect the bottom end from moisture, so I went to my stash of gaskets, selected the best one available, placed it between the freshly cleaned surfaces and installed all the bolts again torquing to manual values. The fan assembly then bolted to its bearing that sits on top of the crankcase cover. The finally activity for the night was removing the oil pan, cleaning it thoroughly removing any crumbs (and there were a few), and reinstalling.

Saturday morning I got most of the shrouding installed before it was time to knock off and attend Mikhaila’s cheerleading completion.

Yesterday, I made it out to the driveway around 1:30 and had Ringo on the ground and running two and a half hours later. In that time I: removed Luna’s alternator and put on Ringo’s engine in place of his which had excessive axial movement; swapped the small plastic choke tripper from one of Luna’s carburetors (I’d broken it during disassembly); hooked up all the wires, hoses, and gas lines; remembered to tighten the front transmission mount nuts; attached the rest of the shrouding; replaced the oil filter; and filled the crankcase with Shell Rotella 30 weight. Before connecting the coil wire, I cranked the engine until the TEMP/PRESS light went off. That ensured oil would immediately flow once the engine started plus it served to refill the carburetor bowls. I did a dance in my head when, after reconnecting the coil wire, one more turn of the key rewarded me with a smooth running powerplant. While one of the lifters was clacking, I wasn’t surprised since the engine had sat for so long, and, sure enough, the clack went away within fifteen minutes. I made many checks under the engine as I occasionally blipped the throttle. Happily, nothing was dripping. TYL!

This morning, he started right up and provided me with a trouble-free commute to work, as well as nice run to the mall at lunch. Sadly, there are still a few less significant issues that need addressing - and I plan to do so before returning Ringo to Ariel. First, the transmission shifter cable still leaks. I have tried the heatshrink tubing fix and it didn’t work. I’ve also tried the cut fuel line with silicone and hose clamps and it didn’t work. Today I ordered a roll of Rescue Tape, and, hopefully, the proper prep and installation of this magical stuff will stop the drips. Second, the dashlights do not work. I’ll fix that this evening by bypassing the dimmer rheostat on the headlight switch. That means a pull of the knob should result in maximum dash illumination. Third, I really want to pull the driver’s seat out and swap the upholstery onto the new, firmer seat I got a few weeks back, and then install that into place. Fourth, I need to install the lower shrouds with thermostats since Fall has come to Baltimore at last. Finally, it’s been a while since the backup lights worked, and that should be an easy fix I can also affect tonight.

Thursday, October 17, 2013

A Little About Ringo and A Lot About Glinda

The Ringo update is quick and easy. The new cylinder, piston, and wrist pin arrived yesterday from Clarks, and wow are they pretty. I took the piston and pin along with Ringo’s old piston/rod assembly to a machine shop this morning to have them install the new piston on the old rod. It was finished by lunch, so I ran over and picked it up. Thirty dollars well spent.

Now on to the recently troublesome Glinda. As I described in Monday’s posting, Ariel was stranded once and inconvenienced a few more times by Glinda’s “chugging” followed by the engine dying while Ariel was driving her on the beltway. My thought all the time had been this had been caused by too much pinging due to the low-octane gas she’d put in the tank. Well, Ariel did come by that evening and took Glinda for her next day commute on the beltway. I didn’t hear anything from her that morning, so I assumed all was well, but as I was putting my first fork-full of a delicious dinner into my mouth, the phone rang. It was Ariel, and Glinda had done the exact same thing, and now they were sitting on the side of the beltway. I asked her if she thought she could make it to a gas station to fill the tank with premium, and she told me she’d try. I replied that if she got Glinda here, she could take my truck until I got Ringo back on the road. About twenty minutes later, Ariel walked in the door, we traded keys, and she continued on her way home.

I made the next morning’s commute with caution and trepidation, not exceeding 60 mph, and Glinda showed no signs of bad behavior. The same was true of the drive at lunch and the drive home. Thinking everything was okay again due to the 93-octane in her tank, I slept the sleep of a car-woe-less man that night.

My automotive contentedness was short-lived, however, as I traveled down the interstate the next morning. During a 70 mph cruise up a slight incline, all of a sudden, and without any warning, Glinda began to quickly lose power. I pressed down farther on the gas pedal, but Glinda’s deceleration continued until the engine died. It was as if she’d just run out of gas even though I knew she still had over three-quarters of a tank. I sat on the side of the road for a couple minutes typing and sending a text to the lovely Loriann telling her of my current situation. With a turn of the key, her engine went into a higher-than-normal idle, but it would respond to blips on the throttle. I put the shifter in Drive and eased away from stop staying on the shoulder and out of traffic until we were going at least 50. She seemed a little down on power, but we made it the last mile to my parking spot. That afternoon, I had to go to Walter’s house to pick up the Ringo bits I’d left there last Thursday. Halfway there, while doing about 60 on an uphill, she began to die again. This time, I let up on the gas, put the flashers on, and cruised along in the slow lane at about 45 until I exited the highway. On surface streets she seemed to run fine, but when I put her in Park in Walter’s driveway, she was idling high again. Irrrr. The rest of the drive home was on surface streets and we made it without incident.

After dinner, I disconnected the fuel line from the gas tank and blew air through it. It seemed to be clog-free since bubbling was heard almost immediately at the tank. I also, pulled the carburetor fuel filters and inspected them – both were found to be clean. This morning we made the morning trip to the machine shop again without any untoward behavior. I’m going to R&R the fuel pump tonight with a brand new one to see if that solves the problem. My drive in tomorrow morning will include another 70 mph blast, so we’ll see then if the problem is solved.

Monday, October 14, 2013

It’s Been Interesting

The last few days since my last post have been, car-wise, a myriad of disappointments ended by a single moment of relief. To begin the downward spiral punctuated by an up-tick, I went home early last Wednesday and pulled some more bits off Ringo's engine until I'd freed the #2 piston/rod assembly from his crankshaft. I found, sadly, that crumbs of damaged piston ring had made their way into the #4 and #6 combustion chambers. This disconcerting discovery does not necessarily spell the death knell of the engine, but does mean I get to do some more thorough cleaning before I button everything back up. To end the evening, I filled a milk crate with a half-dozen cylinders from my stash (an even mix of '64 and '66 vintages), the aforementioned piston/rod, and two others stamped with "2" from my stash (one from Heidi's original '64 engine and the other from CorsaVert's 140 powerplant). This, and an engine block half to be used as fixture while honing, were placed in the bed of my truck before I called it a night. The next evening I left my desk and followed a buddy from work to his garage where we intended to play matchmaker with the milk crate's contents. It was our intention to measure cylinder bores and piston diameters and create a set that met Chevy's specified clearances of .022-.031 inch at the top land and .0011-.0017 at the skirt. Soon after Walter began measuring parts, I had the "duh" moment when it occurred to me that half the cylinders I'd brought (the '64 ones) would not feasibly work in Ringo's current LM engine. Engine-wise 1964 was an odd year for the Corvair. While Chevy increased the stroke to increase displacement, and thus horsepower and torque, of the flat-six, they kept diameters the same. Then, in 1965, they bumped up the diameter at the cylinder-to-head interface. While a smaller '64 cylinder would fit inside the larger head of Ringo's transplanted '66 engine, there were head gasket unknowns I didn't want to delve into. With that decided, I removed the three older cylinders from the matchmaking exercise. With the reduced number of players, it didn't Walter and I long to determine that even the largest piston placed into the smallest cylinder would result in a skirt clearance that significantly exceeded spec. And this gap would get worse still once he honed the cylinder's bore as would be required. The next morning I placed a call to Clark's Corvair parts and ordered a new LM cylinder and piston adding over $100 to Ringo's dent in our finances. Speaking of spending, Corvair Ranch's proprietor, Jeff, was able to dig up a couple loose GNP compression rings and is mailing them to me to replace the two broken ones. This saved me quite a bit since I didn't have to buy a full set (the way they're sold by the 'vair parts vendors).

The next afternoon (Friday), I drove down to NC to spend a short weekend with daughter, Brianna, son-in-law, Nicholas, and bro-in-law and sis-in-law. We all went to the NASCAR race Saturday night which was AWESOME! However, Corvair-wise, that day started on a bad note when I got a phone call from Ariel informing me that, while going round the beltway, Glinda was "chugging" and then lost power. The two rested on the side of the road for a few minutes, before Ariel was able to Glinda re-started and continued the rest of the way to work. A few hours later, a text from her informed me that she'd mistakenly put in regular gas. I quickly replied that this screw-up was putting Glinda's engine in grave danger, and she needed to get the bottle of octane booster off my garage shelf and empty its contents into the fuel tank as soon as she could make it home. Well, she never made it home, and I got "the call" from her that Glinda's engine had again died after chugging. This time, after waiting to let things cool down, it wouldn't stay running. She ended up being about 2 miles short of making it home, so the lovely Loriann had to go and bring her (Ariel) home. That bit of news put an immediate damper on my day, but, fortunately, the stock-car race started soon after and my mind was soon off my Corvair woes.

Yesterday, after my LONG drive back from Charlotte, I donned grungies, tossed the tow stuff into the truck, and went to rescue Glinda from the side of the road. An hour later I had her unhitched in front of the house ready for me to see if her engine would start, and if so, what kind of untoward sounds would emanate from her assumed damaged engine. Well, to my relief, the engine started right up settling into a typical idle – no nasty noises, no chugging. TYL!!!! After verifying each cylinder was contributing to the engine's output, I took her for a quick spin around the neighborhood. Finding nothing amiss, I poured the octane booster into the gas tank and then called Ariel to tell her she could cancel her rental car reservation.

All's well that ends well? Well, I do have to get Ringo back on the road, and for that I need to wait for tomorrow's scheduled parts delivery.

Monday, October 7, 2013

Busted Rings

Friday evening I ventured out to the driveway and set about determining the extent of Ringo’s malady. I started by pulling all the spark plugs inspecting the tips and not finding too much burnt oil. Next, I tested the compression of each cylinder starting with the right side (1, 3, and 5). Each measurement was in the 125 to 140 psi range – good numbers. I found number 2 to be the offending cylinder when a few rotations of the engine only got the needle of the tester up to 25 psi while attached to that spark plug hole. The last two, fortunately, were back up in the 130s. That ended my garage time for the day.

The next morning I woke up early, grabbed the keys to Glinda and drove up to Hunt Valley for the weekly Coffee and Cars get together. I was not disappointed as the highlight vehicles (to me) included a BRAND NEW 2014 Corvette (stunning), a right-hand drive Ford GT40 (smaller and lower than expected), a couple Alfas, a very nice NSX, an early-70s Westphalia (VW bus), and a ’68 Firebird with the overhead cam (OHC) Sprint 6 engine that I’d love to put in my LeMans someday. While wandering amongst the awesomeness, I was approached by a guy I’d met the last time I’d attended. He reminded me his name was Chuck, and then proceeded to tell me that, after our last conversation, he went out and bought himself a ’64 Spyder convertible. I congratulated him on his purchase and invited him to become involved in our local club. He replied by inviting the club to hold a meeting at his “shop.” His “shop” is a shared facility in a industrial park with a lift, a bunch of secure indoor and outdoor storage areas, and a meeting room complete with a HDTV. He went on to describe how the tenants of this shop have invited other clubs to come and, typically, they start early on a Saturday with donuts, have a demonstration such as splatter painting a trunk or installing weatherstripping, and follow that up with pizza for lunch. He left me with his business card, and I’ve already been in touch with him via e-mail about scheduling a January meeting. The lovely Loriann, after I related the story to her, recommended getting an upholsterer to come in and demonstrate installing a convertible top using Luna as the subject. Wouldn’t that be cool? More to follow.

Once back home, I returned to Ringo. It only took a couple of hours to tear down his engine far enough to remove the number two 2 cylinder exposing two broken compression rings. Close inspection of the piston showed it to be undamaged (TYL). Also, close inspection of the broken rings indicates very little, if any, of the ring material is missing.

Given that, I’m at a bit of a crossroads right now regarding how far I go to get Ringo back on the road. Since the damage seems isolated to the cylinder and rings, I could, as a minimum find a GUP cylinder from my stash with a bore that best matches the current piston, have it honed, and then install it with a pair of new rings; or, as a maximum, pull the oil pan, crankcase cover, and oil pump, clean everything, buy a new, matched piston and cylinder and reinstall all with new rings, gaskets, etc. I think I’ll go somewhere in between. I’ve already talked with my buddy from work who’s honed and measured parts for me before, and he’s willing to take an evening after work and do the same thing again. I’ve also called Jeff at the Corvair Ranch and asked him if he happens to have a single pair of compression rings saving me the expense of buying a complete set. I’m thankful for good friends.

Wednesday, October 2, 2013

One of the Those Days

Around 1:30 yesterday, I got the call that I dread – the one that starts with, “Daddy, Ringo died and we’re sitting on the side of the road….” I had been warned by an early-morning text telling me he had been chugging during her twenty-mile morning drive. My hope was the issue would clear up. It didn’t. I left work, drove home, changed into grungies, loaded the tow-bar stuff, and drove to his location. In the meantime, Victoria had been nice and gave Ariel a ride to her next destination. Upon my arrival, I took a quick look under the engine lid – a lot of fluid in the right carburetor region. Hmm; stuck needle-and-seat perhaps? I should be so lucky. I got him hooked up to the truck and we were parked back in front of our house by 3.

Loriann pulled up minutes later with a new grease gun and a cartridge of synthetic grease so I could finish lubricating the joints. The hand pumper seemed to do the job with a few strokes at each zerk fitting resulting in a small bit of grease peeking out of each rubber boot. Since Ariel was going to get to drive Glinda while I dealt with Ringo, I decided to keep the proven stock wheel and tire set on the car. Once off the jackstands, I took her for a spin around the neighborhood. No untoward twitching, no nasty noises – all must be good.

This morning the lovely Loriann drove Glinda to a 10 o’clock appointment at the local Goodyear shop. I had verified the appointment earlier and also verified there would be no charge. At 11:15, they finally drive Glinda onto the alignment rack. Ten minutes later, the technician backs her off the rack and announces the check can’t be made since the left front wheel is not tight. Hence the aforementioned loose bearing. Sadly, all it would have taken to tighten was a couple minutes for the guy to pull off the dust cover, remove the cotter pin, turn the nut, and replace the pin and cover. Irrrr. Now I get to take it back some other morning. I was VERY careful to mark the locations of the camber bolts, so I think everything is pretty darn close to where it needs to be anyway, but a free check is a free check.

Back to Ringo. With Glinda out of the driveway, I fired up Ringo’s engine and backed him to the entrance of the garage. Yes, it was definitely chuggy, and worse still, it wasn’t gas around the right carb, it was oil. Additionally, there were signs of oil around the dipstick. These point to an excessive blow-by condition caused by piston rings failing to do their job. The chugging is probably is probably a few spark plugs that are too clogged with burnt oil to do their job. A compression check on all cylinders is the first step in diagnosing what’s causing the blow-by. Sadly, it was this same condition that prompted me to put in a rebuild in the first place. The problem, I’ll bet, is that I tried to re-use pistons and cylinders. Improper honing or too much clearance resulted in rings that never seated.

While the PT Cruiser isn’t part of the fleet, all the work I get to do on it will take me away from my ‘vair-time. I priced the parts and they came to about $600. I also went through the manual and none of the work looks like it’s beyond my skill level or will require expensive tools I don’t have. The question of the day is, “Where will I do the work?” TwoTone is Group Red (see sidebar) in the garage without front wheels, so rolling him out is problematic. Also, as long as Ringo’s out of commission, the family is one car short if I also take the PT Cruiser down for a few days.

Yep, it’s been one of those days.

Monday, September 30, 2013

A Big Dent

and a set of 14” Torque Thrust wheels for my LeMans.

I also selected a gasket set to re-seal TwoTone’s engine, a Hurst shifter and LM manual shift dash for Glinda’s transformation, a complete LM engine block (all cleaned up and read for assembly) to replace the 140 block that’s still greasy and has broken bolts stuck in it, an interesting custom dual exhaust pipe with a crossover for Glinda, a set of brand new VelveTouch brake shoes for the next time she and I hit the track, and a GUP Powerglide shift cable for Ringo. I’m reviewing the parts list and photos to see if there’s anything left that I’m still interested in. At the same time, I’m struggling with where I put all this new stuff.

Speaking of Ringo, I answered a local e-mail offering a free bucket seat to the first person willing to drive to Laurel, MD to claim. I immediately replied since Ringo could really use a new driver’s seat that had enough life left in to to allow Ariel to see over the steering wheel. That seat is now sitting on Luna's engine lid waiting for me to have a day where I can do a seat cover swap with Ringo's sad seat.

I did get a few hours of garage/driveway time this weekend. Friday night, I disassembled Glinda’s front suspension enough to extract the two lower control arms. Saturday, after helping with the sale setup (which included loading all my buys into the bed of my truck), I stopped by guru Gary’s house and borrowed his balljoint R&R tool. When I got home, I drug Mikhaila out to the garage where she applied the rest of the primer coat to TwoTone’s gas tank while I did battle with pressing out the old balljoints and pressing in the new. When we were both done, she and I disassembled TwoTone’s left front brake assembly, disconnected the incoming hard brake line from the old flex line, and tapped out the innards of the wheel cylinder. Just by virtue of us being able to tear down the cylinder assembly, I’m confident the bore will be in usable shape after a good honing.

After dinner, she was too tired to continue, so I went back out to complete Glinda’s suspension renew and had the last bolt in place and the rubber of the new-to-her front wheels on the ground by 10:30. Only a few issues: 1. it appears my grease gun doesn’t have the gumption to pump grease into the new joints - I’ll buy a new one this evening; 2. the right front tire was flat – hopefully it’s just from sitting for a few months; and 3. I’m just not sure about how I’ll like Glinda’s stance and look with the new-to-her IROC wheels and tires. The front tires are lower profile 205/50-15s while the rears are 225/60-15. With the fronts being about two-and-a-half inches smaller in diameter, I decided to leave Glinda’s front springs alone rather than executing my original plan of cutting off another half a coil - I figured the difference in tire diameter would drop her front enough to level out her current up-facing rake. That may still be, but the look I need to get used to (or not) is front tires that look tiny in the large wheelwell. I’ll drive her with the new set up for a while and see if it grows on me. I still have the option of swapping the stock steelies and tires back on. Photos forthcoming once she’s completely re-shod.

Wednesday, September 25, 2013

It Ain’t Easy Selling Parts

Monday, September 16, 2013

I Love a Productive Weekend

Friday, September 13, 2013

Not Too Small

Tuesday, September 10, 2013

Parting Will Be Such Sweet Sorrow

Sunday I had one of those bittersweet moments when I sold my buddy Rich’s Corsa, but that’s what was meant to be. A large part of me was hoping that Glinda would sell first so I could become the Corsa’s new owner, thus saving me the cost and effort of converting Glinda to a 4-speed car. I am, however, very glad to have found an enthusiastic Corvair guy (he already has a Spyder) to bring this really cool car back to glory. In fact, he offered to hire me to do the work. I had to tell him I was way too busy to take on another project. The car still sits in front of the house waiting for the buyer to return this weekend with the balance of the payment. It’s rough seeing the car sitting there knowing it’ll be moving on in a few days.

So it is with renewed vigor I press on with my initial plan to re-work Glinda into a capable track car that’s also a reliable, comfortable daily-driver. With that in mind, I pulled out the 140 HP engine block halves that afternoon and started cleaning them up. I removed the cut off head studs and soaked the three broken crankcase cover bolts. My plan is to piece-meal the build of this drivetrain over the Fall and Winter with hopes of installing it in the spring. I’ll start by inspecting and measuring the crank, buying the right-sized main bearing set, and reassembling the block halves with a cleaned and lubricated (protected) crankshaft and camshaft. I’ll then mount that on an engine stand in the garage, and do the buildup from there as time and money allows.

The package from Clark’s containing two new carburetor shafts showed up yesterday, so Mikhaila and I now have all the parts to rebuild TwoTones carburetors. I’m anxious to have these done because I intend to test them out on Glinda and see if the hard throttle engine bog is fuel or ignition related. Now I just need to get her to join me and we’ll tackle carb reassembly together. Nice that there are two carbs – his and hers.

Monday, September 9, 2013

I HATE Rust!

Here is the finished product.

Wednesday, August 28, 2013

Still Plenty Going On

With the responsibility of helping Rich’s family get rid of a good portion of his collection of cars and parts, it seems as if the fleet has grown again. Saturday morning I met a man who drove up from Richmond to consider buying Rich’s Corsa. He very carefully looked over the entire car before we even started up (good for him). He commented on how wonderful the photo montage I put up on Flickr was – all the areas of concern were included and he wasn’t surprised by anything he saw now that he was looking at the actual car. He did, however, point out some bubbled pain on the top front edge of the dash – right under surface rust at the base of the windshield – and confessed his concern for the condition of the metal in the channel. We then fired up the engine and it settled into a nice, low idle. After a few minutes of listening and blipping the throttle, we took it out for a test drive. What a BLAST! I’d never driven a LM with a manual transmission, nor had I ever driven a 140-powered ‘vair. I could really get used to it though. The shifter in this car has very short and positive throws – very different from Lucy’s EM shifter. And the power - oh my goodness! 'Nuff said.

I shared with Vince how badly I wanted to buy his dad’s car, but that I needed to sell my ’68 first. I went on to tell him that I’ve had some e-mail conversation with a gentleman in MD looking for a Corvair for his wife who’s supposed to be coming up to look at both the Corsa and my ’68 sometime next week. Depending on what he does, I’ll decide what I’ll do next. If he doesn't buy either, I may put the Corsa on eBay, or I may put Glinda on eBay. I just don’t know.

The other vehicle I’m helping to sell is a cool dune buggy kit. It’s an Action Roadster that Rich picked up a while ago and has since sat in his garage. I’ll put it on Craigslist next week and hope a buyer finds it.

On the home front, work continues on TwoTone. I just placed an order with Clark’s for parts that will start the overhaul of that car’s brake system. Soon to arrive will be brake hoses for front and rear as well as wheel cylinder rebuild kits. In the meantime, Mikhaila and I have been continuing our carburetor work. All the parts have finished their bath in carb cleaner and are laid out on the workbench with the two rebuild kits awaiting reassembly.

Monday, August 26, 2013

Still Nameless, Two-Tone FINALLY Gets Some Attention

The momentous occasion of getting Mikhaila out to the garage occurred yesterday. She actually seemed like she enjoyed it and wanted to do all the tasks without help – only giving in when something was too tight to loosen or remove. I started by having her tear down the two carburetors and then we moved on to a greasier task. She jacked the front end up, placed the jackstands, removed the front wheels with an air wrench, and pulled off the front wheel hubs before I let her quit for the day.

While she was working on her portions of the project, I was attending to prepping the engine for awakening from a LONG sleep. I pulled the spark plugs and shot some 30wgt into each cylinder. Then I cleaned the new-looking ends of the plugs and pulled apart the distributor all the while letting the oil do its thing. I lubed and checked out the centrifugal advance weights and then put in a new points plate with a good-looking set of points and condenser. Finally, I removed the hold-down hardware for the distributor in preparation for spinning the oil pump after I put in new oil and a filter. At that point, I figured I’d given the oil enough time, so I gingerly put a wrench on the harmonic balancer bolt and gave the end a tug. Lo and behold, the crank turned! After sitting for at least 30 years, this engine was a testament to indoor storage.

Once the crankcase is filled with new oil, a spare battery is hooked up with new battery cables, and the carbs are rebuilt and installed, I’ll rig up a gravity feed fuel system (funnel in the end of a fuel hose) to supply them with gas. Then we’ll fire it up.

Though all this work, I am quite pleased about the rust-free nature of this car. I've yet to find any rust-through. When we strip out the interior we may discover some, but that'll be a surprise given what I've seen so far.

Thursday, August 15, 2013

Still Quiet on the Fleet Front

Ringo has been behaving – no new complaints from Ariel other than a warning I’ll probably have to replace his starter again since there have been a few times, she’s turn the key and the Bendix has not engaged, but it’s never stranded her – yet.

Since Glinda is the only fleet member with issues, the rest of this post is about her. Last Saturday I filled the pickup’s bed with wheels and tires and drove to the local Firestone store. A couple hours and $60 later, her green wheels were shod with the best 185-80/13 tires I could pull from my stash. She’s sporting quite old-school look with her dog-dish hubcaps. The following shows her with her EM caps, but I’ve since changed to a set of LM that would have been stock for ‘68s.

Since Glinda is the only fleet member with issues, the rest of this post is about her. Last Saturday I filled the pickup’s bed with wheels and tires and drove to the local Firestone store. A couple hours and $60 later, her green wheels were shod with the best 185-80/13 tires I could pull from my stash. She’s sporting quite old-school look with her dog-dish hubcaps. The following shows her with her EM caps, but I’ve since changed to a set of LM that would have been stock for ‘68s. While running relatively well getting me to and from work and a car show, is showing really low gas mileage and poor engine response both when I floor (it almost dies) and when I try accelerating at freeway speeds. I thought it was an electrical issue, so I gave her a full tune-up (new rotor, condenser, points, cap, and cleaned up the spark plugs [my apologies for the camera focusing on my knees instead of the more photogenic plug ends]). This decreased the high speed missing, but didn’t get rid of it altogether, but it hasn’t seemed to affect the mileage. I don’t want to believe the newly rebuilt carburetors are the issue, but I need to rule them out. I’m going to borrow Luna’s (even though I’m unsure of their provenance), and see if, after installation and balancing, I address at least the full-throttle frustration and high-speed disappointment.

While running relatively well getting me to and from work and a car show, is showing really low gas mileage and poor engine response both when I floor (it almost dies) and when I try accelerating at freeway speeds. I thought it was an electrical issue, so I gave her a full tune-up (new rotor, condenser, points, cap, and cleaned up the spark plugs [my apologies for the camera focusing on my knees instead of the more photogenic plug ends]). This decreased the high speed missing, but didn’t get rid of it altogether, but it hasn’t seemed to affect the mileage. I don’t want to believe the newly rebuilt carburetors are the issue, but I need to rule them out. I’m going to borrow Luna’s (even though I’m unsure of their provenance), and see if, after installation and balancing, I address at least the full-throttle frustration and high-speed disappointment.Finally, I can report I did seal around her windshield and it appears I was successful in stopping the under-dash puddling.

Friday, August 2, 2013

Glinda’s Body Tag and Build Sheet

I was surprised that I never got around to posting and decoding Glinda’s body tag info. I’ll rectify that right here and now. Starting in the upper left corner, the 02B signifies she was built in the month of February (2) and the second week of that month (B). The E to the right means her interior was painted Black. Her STyle is a 1968 Chevrolet (1) 500 (01) sport coupe (37). She was built in the Willow Run (WRN) assembly plant and was the four-thousand, two-hundred and fifty-seventh Corvair assembled there for the 1968 model year. Her TRim number of 703 indicates Black Pattern vinyl bench seats, front and rear. Finally, the K-K prior to the word PAINT corresponds to her Tripoli Turquoise exterior both body and roof.

So how does this stack up against the build sheet? Everything readable across the top line agrees with the tag. An exhaustive search of the internet has not turned up any decoding information for all the numbers that appear on the rest of this sheet. I posted it on the CorvairCenter forum, so we’ll see if anyone can reply with some good information.