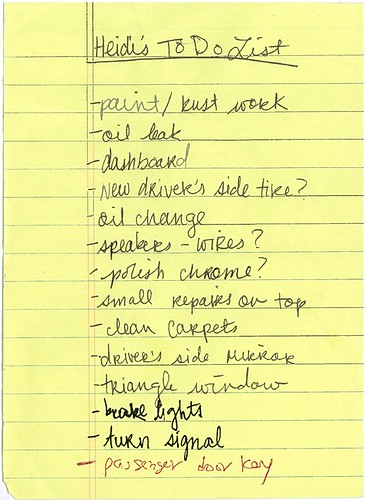

After hours and hours of prep including welding, Bondo’ing, priming, and sanding Heidi was ready for paint yesterday evening. Since I didn’t want to rush through the painting and clearcoating, I decided to get up early this morning and do the shoot in the cool of the day. I truly wish I had the opportunity to paint a car more frequently than every five years. It's really a lot of fun when everything's going down right.

Wait - back up a second. Actually four days. Given all the adventures of the prepping process, I must do some event elucidation. Thursday, with Heidi’s front up on ramps, all her rusty exterior spots received two coats of POR-15 followed by an application of their Tie-Coat primer. The inside of the patches and the cavity the patches enclose were also hit with the POR-15. After fitting the passenger side patch into place using vise-grips and the headlight bucket, it was time to break out the MIG welder. First, tack-welds every inch or so and then filling in between the tacks. The process was

repeated for the other two patches. Next the flap wheel on the grinder smoothed out the welds followed by a complete wipe-down and epoxy primer sprayed over all the exposed exterior metal. I had just enough Bondo in the can to smooth out the welded areas and a few other rusted out places. After some serious Bondo sanding, I spot-sprayed some more of the epoxy primer to seal the bondo and cover any metal I may have exposed with my sanding. Once that had cured, I laid three coats of urethane primer.

After letting the primer cure overnight, I spent the better part of Sunday afternoon wet-sanding every square inch of the Heidi's now blue-grey body. That was followed by two rounds of rinsing off all the residue. Finally, this morning I was up with the sun and out in the garage. Another wipe-down with a surface cleaner and it was do-or-die time. I mixed up the first batch of metallic silver and poured it through a filter and into the gun’s reservoir. A large piece of cardboard was my initial target. I wanted to make sure the setting I’d used for primer would be okay for the paint. It looked good, so I commenced shooting. Foolishly, I started with the trunk lid and laid down the first coat too heavily by not moving my hand fast enough. Irrrr. Even worse was the sagging I got on the passenger door. The three subsequent coats were more properly applied and covered up most of my initial errors. With four coats of color applied, I moved on to the clearcoat. Three light-medium layers finished off the job. I’d post some pictures, but Brianna prefers to be surprised in person. She’ll be up early next week, so I’ll put the photos in

my Flickr Heidi set then and link to them from here.

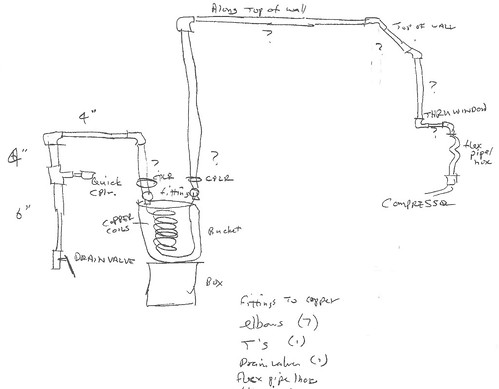

Is it perfect? Heck no, but then it didn’t cost me five figures. It needs some wet sanding and buffing to be as nice as possible, but that will wait for another day. On a positive note, the new air system performed flawlessly – no fish eyes.